AOFENG SH988 curtain wall silicone structural adhesive is a

one-component, neutral, room temperature curing, a variety of substrates with

excellent bonding properties, no corrosion, excellent weather resistance, Little

change in the range of -20 ℃ -100 ℃ performance; good compatibility with the company other

neutral silicone rubber.

Main use

1, glass, glass roof, aluminum, aluminum plate and

other curtain wall structural engineering structural adhesive seal.

2, a variety of other industrial and construction

purposes.

Construction Summary tips

1, silicone adhesive substrate surface to be bonded must

be clean, dry, no dust, no oil, no water exists.

2, to clean the substrate surface with a clean

non-velvet white cotton cloth and stained toluene or acetone solvent to clean

and dry, and make injection within one hour.

3, to ensure the glue sticky joints without gaps, and modify

before curing if needed.

4, on-site substrate adhesion and compatibility test

and customer satisfaction test must be made before use.

5, silicone sealant construction site requirements: environment

needs to clean, dry, well ventilated. Indoor temperature should not be lower

than 15 ℃, and should not be higher than 27 ℃, relative humidity should not

be less than 50% The thickness and width of the glue should meet the design

requirements, and the width should be at least 7mm, the thickness should be

6mm-12mm.

Application restrictions

Should not be used on the substrate surface which

extrudes oil, plasticizer or solvent substrate, or on sites which are continuous

flooding or year-round wet places, nor airtight places.

This product has not been tested or stated for medical

or medicinal purposes.

Safety Precautions

1, silicone sealant curing process will release low

molecular substances, the construction site should ensure ventilation, to avoid

excessive concentration of volatile material, which is discomfort (after curing

the cured body without any damage).

2, uncured silicone adhesive to avoid contact with

eyes, if contact with the eyes, please rinse with plenty of water, and to seek

help from the doctor.

3, when not cured, do not let children touch, if

accidentally being eaten, should seek help from the doctor.

Plastic tube packing

Shelf life: 18 months

Net capacity: 300ml

Packing quantity: 24pcs / box

Color: black, transparent

Aluminum

film sausage packing

Shelf

life: 18 months

Net

capacity: 592ml

Packing

quantity: 20pcs / box

Color:

black, transparent

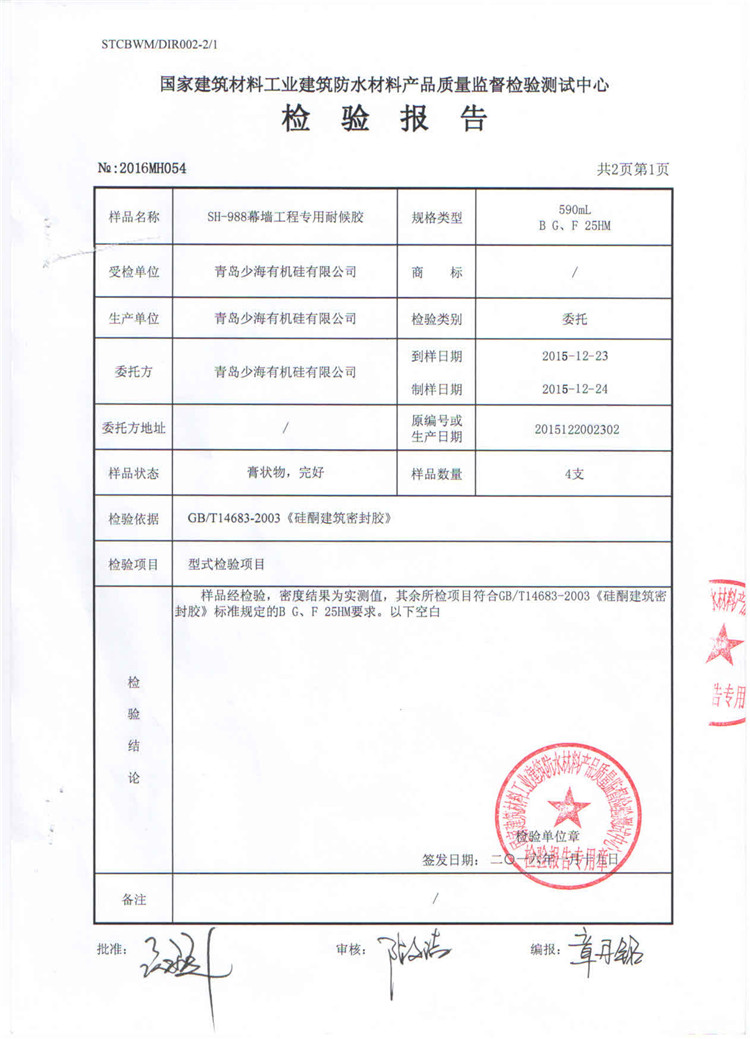

Test report

|

Test report under GB/T14683-2003 B G F 20HM 《Silicone Construction Sealant》

|

|

Seriel No.

|

Item

|

Standard

Regulation

|

Test

Result (Value)

|

Assessment

|

|

1

|

Surface

|

/

|

Smooth

and uniform paste,No bubble,no crust,No particles

|

Qualified

|

|

2

|

Density

(g/cm^3)

|

±0.1

|

1.45

|

Qualified

|

|

3

|

Sag

(mm)

|

Vertical

|

≤3

|

0

|

Qualified

|

|

Horizontal

|

No

deformation

|

No

deformation

|

|

4

|

Tack-Free

Time (Hour)

|

≤3

|

0.5

|

Qualified

|

|

5

|

Extrudability

(ml/min)

|

≥80

|

158

|

Qualified

|

|

6

|

Elastic Recovery Rate (%)

|

≥80

|

85

|

Qualified

|

|

7

|

Tensile Modulus (Mpa)

|

23℃

|

>0.4 or >0.6

|

0.7

|

Qualified

|

|

20℃

|

/

|

|

8

|

Cohesiveness

|

No descontruction

|

No descontruction

|

Qualified

|

|

9

|

Cohesiveness after UV irradiation

|

No descontruction

|

No descontruction

|

Qualified

|

|

10

|

Cohesiveness after cold-pull & hot press

|

No descontruction

|

No descontruction

|

Qualified

|

|

11

|

Fixed adhesion after immersion in water

|

No descontruction

|

No descontruction

|

Qualified

|

|

12

|

Mass loss rate

|

≤10

|

4

|

Qualified

|

|

Base material of testing: glass, anodized aluminium plate

|

Original test report copy