|

|

A one-component, neutral cure designed specifically for the glass structure of a curtain wall. Can be easily used in very wide temperature ranges. Rely on the moisture in the air curing into excellent, durable high modulus, high elastic silicone rubber. Products do not need to use glass primer, can produce superior adhesion. It has the following superior product features:

1. Easy to use: can be used at any time.

2. Neutral curing: no effect on the glass adhesive layer.

3. Excellent adhesion.

4. Excellent resistance to aging and stability;

5. After curing with high modulus performance, but also carrying interface ± 25% of the telescopic displacement capacity;

6. before structural assembly being made, the material samples and assembly drawings must be sent to the professional testing company testing and audit in advance.

High performance silicone adhesive

Products can produce excellent adhesion for most of the building materials, without the use of primer.

It has the following superior product features:

1, easy to use: can be used at any time.

2, neutral curing: for most of the building materials without adverse reactions or corrosion.

3, excellent adhesion: no primer needed, to form a strong cohesive force with most of the building materials.

4, excellent stability and resistance to aging.

5, after curing, produce high modulus performance, also can carry interface ± 25% of the telescopic displacement capacity.

6, before the structural assembly being made, the material samples and assembly drawings must be sent to the professional testing company for testing and audit.

Neutral Transparent Structural Silicone Sealant

A one-component, neutral cure designed specifically for the glass structure of a curtain wall. Can be easily used in very wide temperature ranges. Rely on the moisture in the air curing into excellent, durable high modulus, high elastic silicone rubber. Products do not need to use glass primer, can produce superior adhesion. It has the following superior product features:

1. Easy to use: can be used at any time.

2. Neutral curing: no effect on the glass adhesive layer.

3. Excellent adhesion.

4. Excellent resistance to aging and stability;

5. After curing with high modulus performance, but also carrying interface ± 25% of the telescopic displacement capacity;

6. before structural assembly being made, the material samples and assembly drawings must be sent to the professional testing company testing and audit in advance.

The strength of the structure adhesive is high, can withstand large load, and aging resistance, fatigue resistance, corrosion resistance, life expectancy Stable, suitable for supporting the strong structural parts.

Non-structural adhesive strength is low, poor durability, can only be used for ordinary, temporary nature of the bonding, sealing, fixed, can not be used for structural bonding.

The useful life of the construction project is generally more than 50 years, the components bear more complex stress, directly related to the lives of people, property safety, adhesive glue should be structural adhesive. Structural adhesives are widely used in engineering. They are mainly used for reinforcement, anchoring, bonding and repairing of components. Such as sticky steel, sticky carbon fiber, planting bar, crack reinforcement, sealing, hole repair, spike paste, surface protection, concrete Bonding and so on.

Should not be used on the substrate surface which extrudes oil, plasticizer or solvent substrate, or on sites which are continuous flooding or year-round wet places, nor airtight places.

This product has not been tested or stated for medical or medicinal purposes.

1, silicone sealant curing process will release low molecular substances, the construction site should ensure ventilation, to avoid excessive concentration of volatile material, which is discomfort (after curing the cured body without any damage).

2, uncured silicone adhesive to avoid contact with eyes, if contact with the eyes, please rinse with plenty of water, and to seek help from the doctor.

3, when not cured, do not let children touch, if accidentally being eaten, should seek help from the doctor.

Shelf life: 18 months

Net capacity: 300ml

Packing quantity: 24pcs / box

Color: black, transparent

Shelf life: 18 months

Net capacity: 592ml

Packing quantity: 20pcs / box

Color: black, transparent

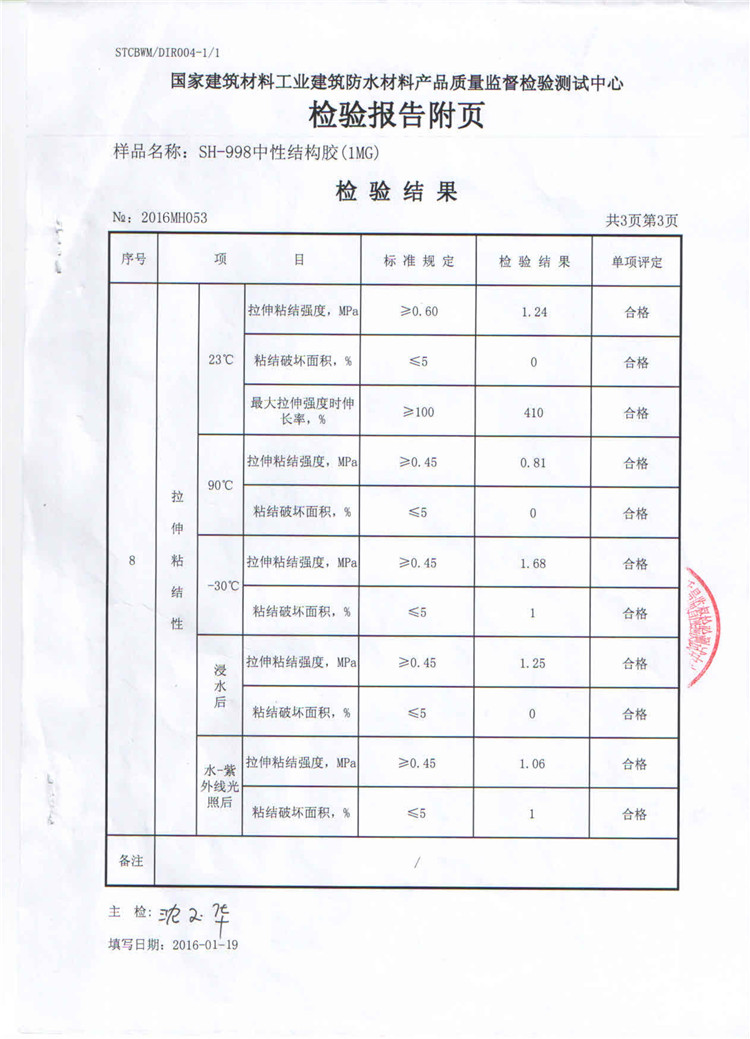

| Test report under GB/T16776-2005 1MG <Construction use Structural Silicone Adhesive> | ||||||

| No. | Item | Standard Regulation | Test Result (Value) | Assessment | ||

| 8 | Tensile bondability | 23℃ | Tensile bond strength Mpa. | ≥0.6 | 1.24 | Qualified |

| Bonding destruction area % | ≤5 | 0 | Qualified | |||

| Extreme elongation at maximum tensile strength % | ≥100 | 410 | Qualified | |||

| 90℃ | Tensile bond strength Mpa. | ≥0.45 | 0.81 | Qualified | ||

| Bonding destruction area % | ≤5 | 0 | Qualified | |||

| —30℃ | Tensile bond strength Mpa. | ≥0.45 | 1.68 | Qualified | ||

| Bonding destruction area % | ≤5 | 1 | Qualified | |||

| After immersion in water | Tensile bond strength Mpa. | ≥0.45 | 1.25 | Qualified | ||

| Bonding destruction area % | ≤5 | 0 | Qualified | |||

| After water immersion and UV light | Tensile bond strength Mpa. | ≥0.45 | 1.06 | Qualified | ||

| Bonding destruction area % | ≤5 | 1 | Qualified | |||

| Note | ||||||

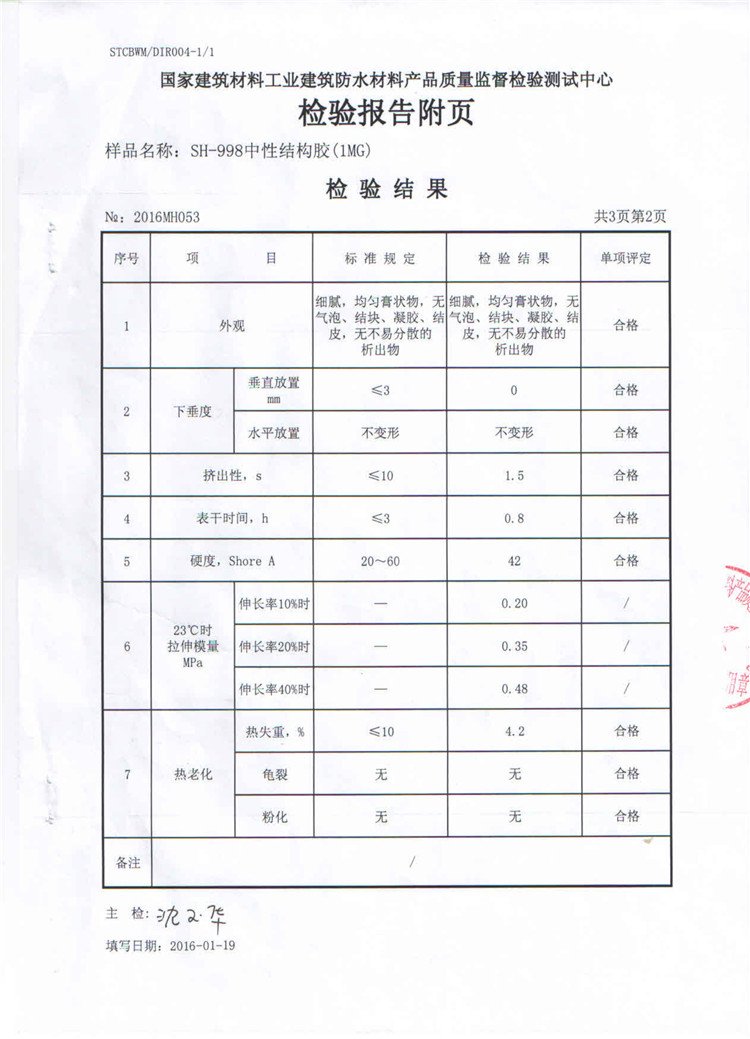

| Test report under GB/T16776-2005 1MG <Construction use Structural Silicone Adhesive> | |||||

| Seriel No. | Item | Standard Regulation | Test Result (Value) | Assessment | |

| 1 | Surface | / | Smooth and uniform paste;No bubble;no crust;No particles | Qualified | |

| 2 | Sag (mm) | Vertical | ≤3 | 0 | Qualified |

| Horizontal | No deformation | No deformation | |||

| 3 | Extrudability (s) | ≤10 | 1.5 | Qualified | |

| 4 | Tack-Free Time (Hour) | ≤3 | 0.6 | Qualified | |

| 5 | Hardness (Shore A) | 20-60 | 43 | Qualified | |

| 6 | Tensile Modulus (Mpa) under 23℃ | Elongation 10% | - | 0.2 | / |

| Elongation 20% | - | 0.35 | / | ||

| Elongation 40% | - | 0.48 | / | ||

| 7 | Heat aging | Weight loss 10% | ≤10 | 0.2 | Qualified |

| Cracked | None | None | Qualified | ||

| Powdery | None | None | Qualified | ||